Disclosure: This post may contain affiliate links, meaning I get a commission if you decide to make a purchase through my links, at no extra cost to you.

Sometimes you just have to cut a bolt, maybe the bolt is stuck or maybe it has become so rusty that it is impossible to get off. The Dremel tool is perfect for these kinds of jobs, it is small enough to get into most tight places, and it uses high-quality cutting discs like the ones on your angle grinder, just smaller.

Trust me, bolts and other metals are easy to cut with the Dremel. But it is important to do it properly, even if the Dremel is a relatively small power tool it can still do some damage. So let’s go through the process step by step.

Links To Every Item Mentioned In This Article:

Recommended Dremel: https://amzn.to/3kYzs2m

Recommended Cutting Wheel: https://amzn.to/3qXtcvC

EZ-Lock Mandrel #EZ-402: https://amzn.to/3nCAx1O

Flex-Shaft For Dremel: https://amzn.to/3cwKNSK

Right Angle Attachment: https://amzn.to/3nKnImd

How To Cut A Bolt With Your Dremel

1. Use Safety Glasses And Gloves

Safety is the BEST, don’t you agree. When cutting metal with a Dremel, safety is actually very important. Cutting discs can break and come flying at you (has happened to me before), there will be sparks from cutting the metal, and as a general rule, we always use safety gear around power tools.

As a minimum, we use safety glasses to protect our eyes from metals and broken cutting discs. Use the type of safety glasses that completely covers your eyes and does not leave any room for materials to reach your eyes. You can also use a safety visor.

In general, gloves and power tools do not match that well, because the gloves can get caught up in the moving parts of the tool and become a security risk. But when cutting metal with a Dremel, I personally choose to use gloves to protect my hands from sparks and hot metal. Decide what works for you.

A tool like a Dremel might still be able to do some harm if your glove gets caught up in the cutting bit. But it’s not nearly as powerful as something like an angle grinder for example.

2. Use The Right Dremel Tool

In this article, I’m going to focus on using the Dremel Rotary Tool. If you have a Dremel 3000, 4000, 4300, 8220, or a similar model, you can use it for cutting metal.

If you have a less powerful Dremel like the Dremel Stylo+, it will take longer to cut through the metal bolt and be hard on the tool. I know that the Stylo+ is not meant for heavy-duty jobs like cutting bolts.

3. Choose The Right Cutting Bit

We have to choose the right bit depending on the thickness of the bolt we are cutting. I recommend using the Reinforced Cutting Wheel For Metal Cutting 99% of the time. This is the most reliable bit used to cut metal with the Dremel, it is also the thickest and widest metal cutting bit.

The reinforced cutting bit uses the EZ-Lock mandrel #EZ402.

The largest bolt a Dremel can cut has a diameter of 2/3-inch (1.7 Cm). Cutting a bolt this large with your Dremel will be hard on the motor and wear out the bit fairly quickly.

You can also use the smaller and thinner metal cutting bits for cutting bolts with the Dremel, but they are more brittle and have a bigger chance of breaking while cutting. And I do not like shards of cutting wheels to come flying at me so I try to avoid them. The smaller bits used to cut metal are the #420 Cutting Bit and the #EZ409 Cutting bit.

4. Mark the Cut And Make A Plan

Use a marker to mark on the bolt where you are going to do the cut. It can be hard to make a straight cut in metal with the Dremel. But the mark will definitely help as a reference.

You also have to take into consideration how you are going to do the cut. Sometimes bolts are located in tight places which can be hard to reach. Do you need to use the smaller flex shaft to reach it, or maybe you need to use the right-angle attachment to get the angle right

!Important: The cutting of metal will produce sparks. Make sure you are not cutting metal close to any flammable material.

5. Set Your RPM

Now we have located, marked, and planned out our cut and we are ready to start cutting bolt. Set the RPM on the Dremel between 30000 – 35000, or the highest speed/RPM your Dremel can get to.

If it is your first time cutting metal with a Dremel, it can seem intimidating to use such a high rpm, it is best to use a high RPM but it is fine to use a lower RPM if that makes you feel safer.

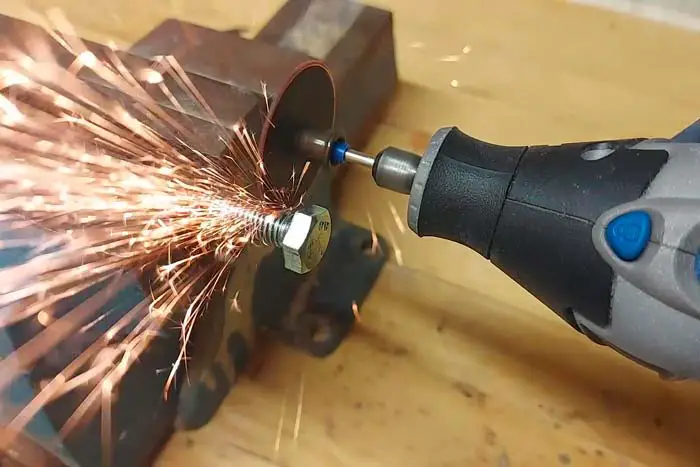

Here is a demo I made, which shows how the Dremel performs when cutting a bolt.

6. Start Cutting

Let’s turn on the Dremel and start cutting.

It is important to cut into the bolt where you have the most stability, and force, this is usually from the right side.

When the Dremel is powered on you can start to move the cutting wheel slowly towards the bolt and the mark where to cut. Keep two hands on the Dremel to improve the stability and precision when cutting.

When the cutting wheel and the bolt make contact, some sparks will come flying. This is normal when cutting metal. Just press the cutting wheel gently into the bolt without applying too much force. Applying too much force will just overheat the metal and wear out your cutting wheel.

The cutting wheel has a tendency to “jump” or flinch when cutting metal. This is more a problem in the beginning when you do not have feel for cutting metal yet, it is very important to keep a steady hand so you don’t lose the Dremel if it “jumps” in the middle of the cut.

Keep a steady hand and you will be fine.

7. Finish the cut

Depending on the thickness of the bolt you might have to work your way around the different sides of it. Remember a Dremel can bolts up to 2/3-inches (1.7cm) in Diameter. But doing so will be hard on the tool, and you will have to replace the cutting disc at least once while cutting.

If you realize that the bolt is too big it might be easier to finish it off with a hacksaw, or just use a loose hacksaw blade.

When finishing the cut you should keep a steady hand and let use a little less pressure against the metal bolt. And when the cut is finishing, don’t touch the metal straight away, it will most likely be too hot.

Let it cool down for at least 30 seconds before attempting to touch it.

8. Now You Know How To Cut A Bolt With The Dremel

Yay, you did it. Now you know how to cut a bolt with your Dremel. And you know what, you can use this method to cut most metals that are smaller than 2/3-inches (1.7cm). You can cut nails, screws, stainless steel, and whatever comes your way.