Jigsaws are commonly associated with cutting wood. But a jigsaw is a very versatile tool and it can actually be very useful when working with metal as well.

To cut metal with a jigsaw we need to use an HSS or Bi-metal jigsaw blade. Secure the metal on a sturdy working surface, mark the line you want to cut, cut slowly and let the tool do the work. A jigsaw is best used for cutting up to 1/8″ (3mm) thick metal sheets or up to 1/4″ (6mm) thick aluminum sheets.

But there is a lot that goes into cutting metal with a jigsaw like what blades to use, dealing with heat buildup and dulling blades, preparing a proper work surface, and what safety gear to use.

So let’s go through how we cut metal with a jigsaw in detail.

How To Cut Metal With A Dremel – Step By Step

1. Which Types Of Metal Can You Cut With A Jigsaw

A jigsaw is best used to cut flat metal sheeting where the shoe of the jigsaw can rest properly against the flat surface of the metal. This will provide stability and reduce vibration.

A jigsaw is not the best tool for cutting odd metal shapes like pipes and or table legs, but in a pinch, it will be able to cut through that as well.

The thickness of the metal a jigsaw can cut through will vary greatly depending on the hardness of the material.

A jigsaw can comfortably cut through 1/4″ (6mm) of aluminum sheeting.

But when cutting a harder metal like steel sheeting, the jigsaw is going to start cutting very slowly after you exceed a thickness of 1/8″ (3.2mm)

There are some types of steel you would not want to cut with a jigsaw. Hardened steel for example is very hard as the name implies and would be a pain to cut through with a jigsaw. You can technically do it, but it is just too much effort and it will dull your blades in no time.

But if you are using a carbide-edged blade, it can cut through thin sheets of hardened steel and stainless steel.

2. Use A Powerful Jigsaw

The cheapest off-brand jigsaws will be able to cut through metal, but it is going to be harder to achieve clean cuts and you will have to invest more time into cutting.

Using a more powerful jigsaw, either an industrial-grade jigsaw or a mid-range jigsaw will make your cuts faster and cleaner, and help you a lot along the way.

A good example of a good mid-range jigsaw is this BOSCH 7.2 Amp (Amazon).

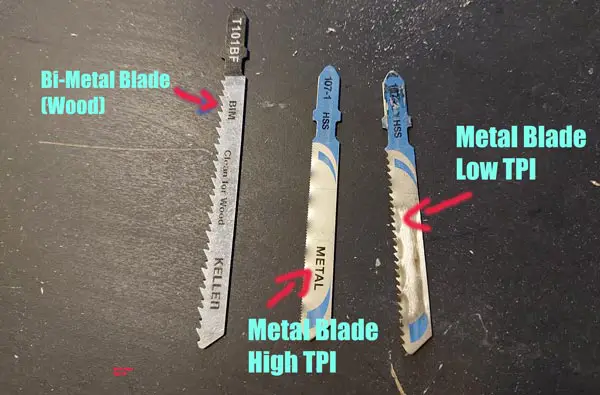

3. Choose A Jigsaw Blade For Cutting Metal

The image above shows a Bi-Metal blade for wood, didn’t have one for metal right now. But a Bi-Metal blade for metal will still have the same BIM writings on it.

I have a complete detailed jigsaw blade guide here: Jigsaw Blades 101 – A Complete Guide

HSS Jigsaw Blades

HSS stands for “High-Speed Metal”. Most of the jigsaw blades we are going to use for metal has HSS written on them close to the shank.

HSS jigsaw blades are less flexible but more durable than the HCS (High Carbon Steel) blades that are used for cutting wood.

This means that the HSS blades last longer and can cut harder materials like steel, but they are less flexible and will break more easily if you try to cut curves with them.

Jigsaw blades for metal will range in teet density from 12 TPI (teeth per inch) to 30 TPI+.

Jigsaw blades with lower TPI 12 – 20 will be more aggressive, can cut through thicker materials, and will cut faster. But they will also leave a more rugged finish on the cut, and get dull quicker.

Jigsaw blades with higher TPI 20+ should be used to cut thinner materials, they will leave a cleaner cut, but will also cut slower.

Bi-Metal Jigsaw Blades

Bi-Metal jigsaw blades are made of a combination of different metals to enhance the quality of the blade. It is usually made of both HCS and HSS.

Bi-Metal jigsaw blades are more expensive than normal HSS blades, but they have a durability that is 2-5 times longer than an HSS blade.

Investing in some good quality Bi-Metal blades for cutting metal is definitely worth it.

Carbide Edge Jigsaw Blades

The carbide edge jigsaw blade (Amazon) is probably the most durable jigsaw blade that can cut through the hardest metal of any of the other jigsaw blades.

But it is also the most expensive jigsaw blade, usually costing upwards of 10$ for one blade.

The cutting edge of the carbide blade is made of carbide, which is an extremely durable metal made from carbon and tungsten mended together.

If you choose to invest in a carbide edge blade for your jigsaw, you can use it for a long time before it gets dull.

4. Set your working surface

Setting your working surface properly is extremely important when cutting metal.

First of all, we want to rest the sheet metal on a sturdy flat surface. If the surface is sort of flimsy, the metal will easily start to vibrate during the cut and we do not want that.

We also have to clamp the down metal to our working surface, preferably with two clamps so it does not rotate during the cut. I prefer using quick-grip clamps (Amazon) because they seem to handle the vibrations better and do not come loose during the cut.

If you are cutting another shape like a pipe, you can secure it in a vise.

We also want the edge of the metal we are cutting to be as close as possible to the working surface. If for example, the metal sheet hangs 10″ (25cm) off the table we are working at, the metal will vibrate more.

5. Mark the Cut

We have to mark the cut before we start cutting. I’ve found that a permanent marker works best for metal.

We want a strong visible line, so we will be able to see the line even if we need to use some cutting oil or coolant.

6. Put On Safety Gear

When working with power tools and metal we always want to be using safety gear.

Eye Protection – Always wear eye protection when using any kind of power tool. When I cut metal I can sometimes feel the small metal pieces hitting the skin on my face and hands.

Hearing Protection – It is a good idea to wear noise-canceling earmuffs when using a jigsaw to protect your hearing. But this will depend on personal preferences and the sound level of the jigsaw.

Dust Mask – The amount of fine metal dust that is produced depends on what type of blade you use in your jigsaw. But it is always a good idea to wear a dust mask when cutting metal.

Metal-Toed Shoes – Metal toes shoes are also a good idea to wear when working with metal. Metal is heavy and can drop onto your foot, you can also be unlucky and drop the running jigsaw.

Gloves – Gloves are a debated topic when it comes to power tools. But a jigsaw does not rotate, and cutting metal with a jigsaw produces a lot of vibration and heat. It is up to personal preference if you want to use gloves or not when cutting metal.

7. Start Cutting

We have now secured our metal object to a sturdy working surface, our protection gear is on, the cutting line is marked and we are ready to start cutting.

Put your preferred blade in the jigsaw, put it into the socket or put the battery in, and turn it on.

After you have started the jigsaw it is important to wait 2-3 seconds to let it reach the speed that the jigsaw is set to.

For harder metals, you might want to use a lower speed to reduce the heat buildup. If the blade and metal get too hot it is going to dull the blades real quickly.

To initiate the cut we rest the shoe of the jigsaw onto the metal first, with a firm grip we slowly approach our marked line with the blade.

Go very slowly in the beginning and get a feel for how the jigsaw reacts to the cutting. It is going to be very slow on some metals, and it is going to be a lot quicker on others depending on the hardness and thickness.

The most important thing is that you do not force the cut, this is only going to result in the blade overheating and getting dull, and it will leave a bad cut.

Cutting metal is very different from cutting wood, it will take a lot longer, so it can take some time to get used to if you have only used the jigsaw to cut wood before.

Following the line is fairly simple when cutting metal with a jigsaw, you can make a pretty decent cut without using any guides. But it is never going to be 100% straight without a guide.

If you want a straight cut, you can use a straight piece of scrap wood or metal and secure it with clamps onto the metal surface. Measure the distance from your jigsaw blade to the end of the shoe, that is how far away you want to clamp the scrap wood/metal from the marked line.

8. Should You Use Cutting Oil When Cutting Metal With A Jigsaw

For harder metals, it can be a good idea to use cutting oil to avoid overheating the blade and the metal. But this will depend on the quality of the blade, the thickness of the steel, the quality of the jigsaw, and how long the cut is.

Metal will get very hot when you cut it, so make sure to not touch it with your bare hands right after the cut. Cutting aluminum and softer metals will not get as hot as hard metals but will still produce some heat.

The jigsaw blade will also be really hot after a cut in metal.

9. Finishing Touches

Cutting metal will produce a burr. A burr is a rough metal edge on the cut line. We want to clean up this metal because it is sharp and doesn’t look so good.

To clean the burr we can use a wide range of tools. We can use some sandpaper, a rotary tool with a grinding stone/carbide burr or we can use an angle grinder with a finishing disc.

10. FAQ: Cutting Metal With A Jigsaw

Can You Plunge Cut With A Jigsaw Into Metal?

A jigsaw should not be used to plunge-cut into the metal. It would take a really long time and the blade would probably break before it could penetrate the metal. But you can drill a hole in the metal and start the cut with the jigsaw from inside the hole.

Can A Jigsaw Make Curved Cuts In Metal?

Making curved cuts in metal with a jigsaw is possible, but it is harder to achieve curved cuts in metal than in wood. In thin metal sheets and aluminum, you will be able to make curved cuts without much problem. A jigsaw is not suitable for cutting curves in thick and hard metal sheeting.

Bi-Metal jigsaw blades for metal are recommended when cutting curves in metal with a jigsaw. Carbide Edge blades work well too. HSS blades can also cut curves, but they will break more easily because they are not as flexible.

Can You Cut Wood With A Metal Jigsaw Blade?

A metal jigsaw blade will be able to cut through wood. But at a slower rate than a wood jigsaw blade. A metal jigsaw blade with low TPI (12-20) will have no problem cutting through slender planks of wood. This is very convenient when you want to disassemble something that has metal fastened onto a piece of wood.

In the image above I use a rough 14TPI jigsaw blade for metal to cut through the lid of a chest that did not fit my trash can. After cutting, it fits.

Conclusion

Hopefully, you learned something about cutting metal with a jigsaw through this article. Cutting metal might seem a little bit daunting in the beginning, but after some practice cuts, you will quickly become comfortable with cutting metal.

Good luck with your metal-cutting journey.