PVC is a type of plastic that a Dremel rotary tool can cut fairly easily. PVC is a hard plastic that will not melt due to the friction of the high RPMs of the tool. A Dremel is not the best tool for cutting PVC, but there are certain situations where we would want to use a Dremel for cutting PVC pipe.

To cut PVC with a Dremel we use the EZ476 plastic cutting wheel. Mark the cut, put on safety gear, secure the PVC pipe, set the Dremel to 20000 RPMs, turn on the Dremel and start cutting slowly. Don’t use too much force and let the tool do the job.

That was the quick version. But there is a lot more that goes into cutting PVC with a Dremel, so let’s get into it.

How To Cut PVC With A Dremel

1. Best Dremel Models For Cutting PVC

The best Dremel models for cutting PVC are the Dremel models that have some power. Like the Dremel 4000, 4300, 8220, 8260, 3000, Lite, and so on.

It will depend on the thickness of the PVC pipe of course. But a weaker model like the Dremel Stylo+ will not be so fun to cut PVC pipes with and will bog up most of the time.

In this article I use the Dremel 4000 (Amazon), this is my favorite Dremel model and I use this most of the time.

2. Safety Gear For Cutting With A Dremel

Cutting PVC with a Dremel is not really a high-risk task. But we still want to use safety gear.

Always use protective glasses when using a Dremel, bits can come loose and pieces of plastic can break off. We want to protect our eyes from these flying objects.

Cutting PVC will produce some plastic dust. To avoid this getting into our lungs we use a dust mask.

Gloves are not really recommended when using most power tools, because they can get caught up in the running tool. If you want to protect your hands with gloves, use a sleek glove that fits your hand well so it does not get caught up in the tool.

3. Dremel Bits For Cutting PVC

The best bits for cutting PVC and plastic are the #EZ476 Plastic Cutting Wheels(Amazon). These bits are designed for cutting plastic specifically, so they work well.

The #EZ476 plastic cutting wheels are usually not included in the accessory kit when you buy a Dremel. But there are some other options if you don’t want to buy a new set of cutting discs, or if you don’t have the time to wait for them to arrive.

The #EZ456 metal cutting discs(Amazon) will also work fine for cutting PVC pipe. Although they are a little bit slower than plastic cutting discs.

The smaller #409 cutting discs will also work for cutting PVC. But keep in mind that these have a tendency to break if you use too much pressure when cutting, so be careful.

The serrated saw blades work surprisingly well for cutting PVC. The sawblade that I used is just a cheap brand made in China.

4. Type Of Cut (Crosscut vs Rip cut vs Plunge)

We have to approach the cutting a little bit differently depending on what type of cut you need to make.

If you just want to shorten the pipe you would want to do a crosscut. A Dremel is not ideal for doing crosscuts. Especially if you want to have a clean and straight surface after the cut. But you can do it if you don’t mind having a little bit of rugged and crooked cut.

But ideally, I would use another tool for crosscutting.

A good tool for cross-cutting PVC pipe is a miter saw, a pipe cutter, or just a hacksaw.

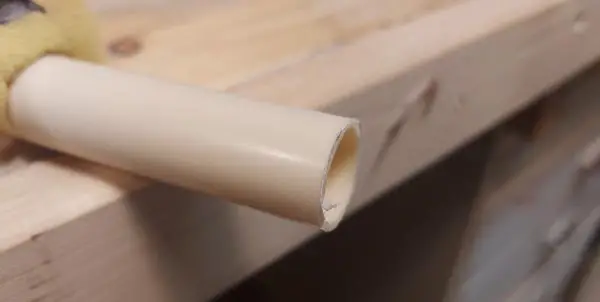

For doing a rip cut in PVC, the Dremel can be great. And this is what I will mostly focus on in this article as well as cutting PVC in general. A rip cut is when you cut parallel to the length of the PVC as you see in the picture below.

The Dremel is also great for cutting all kinds of strange shapes in PVC pipe, for example, if you need to make a V-notch in the pipe.

You can also do plunge cuts with the Dremel. But plunge cuts in PVC are usually done with hole saw bits used with a cordless drill. A Dremel is not good at making accurate circular holes in PVC pipes.

5. Mark The Cut

Marking a cut on a PVC pipe is fairly simple.

Find a corner with a 90-degree angle (I’m using my workbench up against my wall), lay the piece of PVC up against the corner, and use a piece of wood that is half the thickness of the PVC pipe, press the wood piece against the PVC and mark the PVC with a marker or pencil.

6. Securing The PVC

For cross-cutting, you can secure the PVC with a clamp or in a vice. But don’t let the PVC stick too much out from where it is secured, since it will vibrate a lot when being cut if it does.

When rip cutting (parallel cutting) the PVC pipe, I tend to just hold the PVC pipe with my hand. I cut until the halfway point then turn it around and cut from the opposite side.

But be careful when using your hand to secure the pipe, the running bit is closer to your fingers. So do so at your own risk.

7. Cutting The PVC

Cutting the PVC is very straightforward. Just keep a steady hand and start cutting. But I still have some pointers to share.

When cutting plastic with a Dremel you should in general avoid using a high RPM. High RPMs increase the friction and heat buildup which can result in the plastic melting.

But PVC is a hard type of plastic that can handle heat well. So you can actually use a high RPM when cutting. I found setting your Dremel from about 20000 – 25000 RPMs works best for cutting PVC.

Don’t press the bit completely up into the PVC when cutting. Especially for rip cuts. Doing this will leave friction marks on the side of the cut

The tool can sometimes do an uncontrollable “jump”. Because it gains traction on the side of the material because of uneven cutting or being too close to the edge. This “jump” will always go from left to right and is not a big deal if you keep a steady hand.

It might be a little bit frightening the first time, but it will happen less and less as you get used to cutting.

A Dremel is great for cutting odd strange shapes in PVC that other tools just cannot cut that easily. A good example is the V-Cut that you can see in the image below.

8. Other Tools For Cutting PVC

Pipe Cutters are designed to cut PVC pipes in half. They are not that expensive and can be obtained in many different shapes and sizes.

Plastic Pipe Hand Saws are specifically designed for cutting plastic pipes. They are great for cutting PVC and will do a better job than your hacksaw or normal handheld wood saw.

A miter saw will also do quick work out of the PVC pipe and is great for crosscutting.

Sawzall saws with a metal blade can also cut through PVC pipe.