Disclosure: This post may contain affiliate links, meaning I get a commission if you decide to make a purchase through my links, at no extra cost to you.

One of the most important factors for making quality cuts with a jigsaw is the blade. We use different blades for different materials, we can use aggressive blades for making quick cuts or we can use finer blades for a smoother finish.

Since choosing the right jigsaw blade is crucial for achieving a good cut I will go through all the details of jigsaw blades, and by the end of this article, you will know exactly what jigsaw blade to choose for any task.

The following list can be used as a quick general guide when you want to choose jigsaw blades:

- Lower TPI (Tooth Per Inch) blades will result in faster cutting but a rougher finish.

- Higher TPI blades will result in a cleaner finish but slower cutting

- A thicker blade will be more stable and will not bend during the cut as easily

- A thinner blade is better for doing tight turns but will struggle with thicker materials

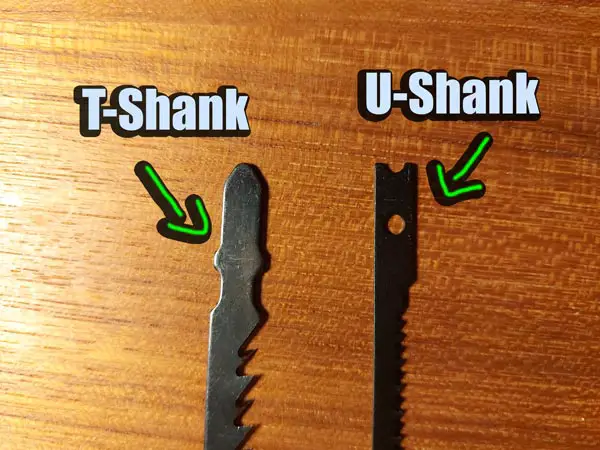

Shank Type

The shank of the jigsaw blade is what connects the blade to the jigsaw. Most modern jigsaws use T-shank blades, but some older ones still use a U-shank blade.

T-shank blades are the standard for most jigsaw brands. A T-shank blade is shaped like a T at the top of the blade.

U-shank blades were very common a long time ago. So if you have a very old jigsaw, there is a chance that it uses a U-shank blade. A U-shank blade is shaped like a U at the top of the blade. Finding U-shank blades in stores can be challenging because they are very much on their way out of the market.

So make sure you know what blade your jigsaw uses before buying, it will most likely be a T-shank. Just check the default blade that came with your jigsaw.

The Different Types Of Jigsaw Blades

A jigsaw blade will usually have a label on them that says what material they are supposed to be used for. On a blade for cutting wood, it can be written “wood” + “fast”, this tells us that the blade should be used for cutting through wood quickly.

The packaging will also show you the most common uses of that jigsaw blade.

Let’s first look at the most common material we use a jigsaw for.

Jigsaw Blades For Wood – HCS

Jigsaw blades for wood are mainly made of HCS, which stands for High Carbon Steel. This is one of the softest materials that jigsaw blades can be made from. This allows the blade to be flexible and handle vibrations without breaking too easily.

HCS blades should be used for softer materials, construction lumber is considered a soft material.

Jigsaw blades for wood can be put into three categories. We have fast-cutting blades, clean-cutting blades, and scrolling blades.

Fast Cutting Blades For Wood

Fast-cutting jigsaw blades for wood have fewer teeth. A normal fast-cutting blade has between 6 to 8 TPI. A blade with fewer teeth will remove more material in each pass and cut faster, but the cut will usually end up looking rougher.

A fast-cutting jigsaw blade is most useful when you want to make quick cuts in wood and you don’t need to worry about the quality of the cut.

A fast-cutting blade is for example great to use when disassembling pallets. I use it for quickly cutting through the ends of the top planks, then I pry the nails off the middle plank, and clean up the rough cuts from the jigsaw with a miter saw.

A fast-cutting jigsaw blade is easy to identify. It is usually written directly on the blade, but the teeth on fast blades are greatly larger than the common clean-cutting blades. When you look at the blade, you can just see that this is going to cut fast.

Want to learn how to make cleaner cuts with a Jigsaw? Check out these 11 Tips For Making Clean And Accurate Cuts With A Jigsaw!

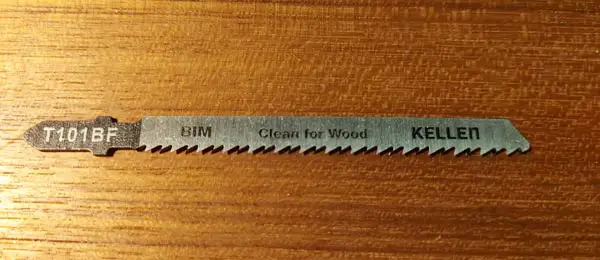

Clean Cutting Blades For Wood

Clean-cutting jigsaw blades for wood have more teeth per inch than fast-cutting blades. It removes less material each pass and results in a cleaner cut, but it will cut slower.

The teeth on the blade are also smaller, which affords a larger surface to guide the cut.

Some clean-cutting jigsaw blades are also thicker and less flexible. This will reduce the chance of the blade bending during the cut.

The blade will often bend during the cut if we cut thick materials or use too much force when cutting. The end of the blade is not supported by a guide and will start cutting off the line on the bottom of the cut, even if you are cutting off the line on the facing side.

On the clean cutting blades, it is often written “clean for wood” or something similar. Clean-cutting blades will look a lot less aggressive than fast-cutting blades.

Clean cutting blades come in very handy when you need the cutting surface to look clean, and can also handle cutting through thicker materials. For example when you want to cut out a hole for the sink in a countertop.

Scrolling Blades For Wood

Scrolling blades have the most teeth per inch of the three common types of jigsaw blades for wood. Scrolling blades usually have 12 TPI. This makes the blade great for cutting curves and contours in thin materials, but they are not good for cutting thick pieces of wood.

The scrolling blades do not always have anything written on the blade like the fast cutting and clean cutting blades, but the shape of the scrolling blades is very distinct from the other blades.

The scrolling blades are smaller and the cutting surface of the blade is smaller than the shank. See the image above for a comparison.

You can do a lot of fine work with scrolling blades. They are great for making patterns and doing tight turns in plywood.

Jigsaw Blades For Metal – HSS, BiMetal

Metal jigsaw blades are made from HSS metal. Which stands for “high-speed steel”. Jigsaw blades for metal blades are tough and can handle cutting through hard materials at high speeds, but they are not as flexible as the HCS blades which makes them more prone to breaking if the blade bends during the cut.

A jigsaw is a great tool for cutting metal, especially metal sheets that are too big to cut on for example a bandsaw. A jigsaw will also be able to cut out odd shapes and curves in metal sheeting.

Metal is a hard material, and a jigsaw is best used for cutting thinner sheets of metal. But a good quality jigsaw, like the BOSCH 7.2 Amp (Amazon) will be able to comfortably cut through 9 gauge ( 3.7mm) thick metal sheeting. This Jigsaw also has a barrel grip, which I prefer over the D-handle Jigsaw grip.

There are three common types of blades that are important to understand when we want to cut metal with a jigsaw.

- 12 – 16 TPI = Fast Cutting Metal Blade

- 18 – 22 TPI = Medium Cutting Metal Blade

- 22 – 30 TPI = Fine Cutting Metal Blade

- 30+ TPI = Extremely Fine Cutting Blade

Fast Cutting HSS Blade

The fast-cutting HSS blade is a blade that is designed to cut metal fast with a jigsaw. It can have anywhere between 12 – 20 TPI.

The fast-cutting HSS blades can also cut thicker metal than the fine-cutting HSS blades. Up to 6mm is the max limit, but 6mm is going to be a slow cut, even with a good jigsaw and blade.

The fast-cutting HSS blade will give a fairly smooth finish on the cut, but not as good as the fine HSS blade.

Fine Cutting HSS Blade

The fine-cutting HSS blade is a blade that is designed to leave a smooth finished cut. It can have anywhere from 20 – 36 TPI.

The fine-cutting blade removes less material with each pass and makes for a cleaner cut. But it will also produce more heat from the friction, so you will not be able to cut thick materials with a fine-cutting HSS blade.

The recommended metal thickness for fine-cutting HSS blades is 0.6 – 2mm (23 – 14 Gauge).

The downside of all HSS blades is that they are very bad at cutting curves since the material of the blades is so stiff and prone to shattering.

HSS blades are best used for straight cuts.

Bi-Metal Blades

Bi-metal blades are jigsaw blades that are made from more than one type of metal. They can combine the flexibility of an HCS blade with the durability and hardness of an HSS blade.

A Bi-metal blade will usually last 2 times longer than an HSS blade and 10 times longer than an HCS blade.

The biggest advantage of using a Bi-Metal blade for cutting metal is that you can start cutting some curves and radiuses without being too afraid that the blade is going to break. The added flexibility and strength really help when cutting contours in metal.

Bi-metal blades are pricier than the HCS and HSS blades, but they are well worth the money because of their extended durability and usability.

The Diablo brand makes some of the best Bi-metal jigsaw blades for use on Metal. You can check out their Jigsaw blades here! (Amazon).

Jigsaw Blades For Harder Materials – Ceramic Tile, Fibreglass, Cast Brick

When we want to cut extremely hard materials with a jigsaw we have to use some specialty blades. Blades for hard materials will have a cutting edge coated with carbide/diamond dust or the saw teeth will have tipped carbide edges.

Carbide is an extremely durable material and will take 10 – 20 times longer to get dull compared to normal jigsaw blades. We also need such a hard material to be able to cut through other hard materials.

With carbide coated/tipped blades, you can cut through for example ceramic tile, fiberglass, and cast brick.

I have this carbide-coated jigsaw blade that I use for cutting ceramic tiles.

Other Specialty Jigsaw Blades

There is an endless supply of different specialty blades for the jigsaw. I cannot go through them all, then this article would turn into a book. But I’ll go through some so you can get a feeling for all the strange jigsaw blades that are on the market.

Precision Wood – Sabrecut

The precision wood blade is extremely wide compared to standard jigsaw blades. It is also thicker. This gives a lot more stability when cutting, and it is great for achieving straight cuts in wood.

You can find it here on Amazon!

Knife-edge Jigsaw Blade

The knife edge jigsaw blade is basically a knife that you can use in your jigsaw. It is designed to cut softer materials quickly and without producing a total mess. (normal blades create a lot of debris).

The knife-edge jigsaw blade can be used for cutting cardboard, polystyrene, leather, and other soft materials.

Downstroke Blades

Since a jigsaw blade usually cuts on the upstroke, the blade will create a rougher cut on the top side and a finer cut on the bottom side.

A downstroke blade will cut on the downstroke. With downstroke blades, the top side of the cut will be the cleaner one, and the bottom side of the cut will be a little bit rougher.

Downstroke blades are great to use when you really need the visible cutting surface need to be as clean as possible.

Extremely Long Jigsaw Blades

You can get extremely long jigsaw blades for cutting large wooden studs. These blades can be 10″ (25Cm) long and cut through materials that are 6″ (15Cm) thick.

Long jigsaw blades can be used for cutting through large wooden studs. But it is hard to achieve a clean cut with blades this long because they are only guided on one side.

Making cuts this large will also require a very good quality jigsaw. Like this one BOSCH 7.2 Amp (Amazon).

Jigsaw Blade For Plastic

You can use the wood-cutting jigsaw blades for cutting plastic. They actually work pretty well for that.

But there are specialty blades for some types of plastic as well. Plexiglass and PVC will have specialty blades that are designed to cut these materials the most effectively.

Common Materials A Jigsaw Can Cut:

- Metal

- Wood

- Tile

- Glass

- Plastic

- Ceramic Tile

- Fibre Glass

- Foam

Best Brands For Jigsaw Blades

Bosch, Diablo, and Dewalt all produce high-quality jigsaw blades. I recommend looking for these brands when buying new jigsaw blades. The cheaper off-brand jigsaw blades will work fine but they are of poorer quality and will dull more quickly. So it does not really become that much cheaper in the long run.

Does Bosch Jigsaw Blades Fit Dewalt Jigsaws

Most jigsaw blades today are interchangeable between brands. It all depends on the shank of the blade. Jigsaws that use a T-shank fastening system can use all T-shank blades. Jigsaws that use a U-shank system can use all U-Shank Blades.

Change Jigsaw Blade

Now that we a learned about all the different types of jigsaw blades, you might want to learn about the several methods of changing a jigsaw blade. Click Here! To read the article I made about changing jigsaw blades.