Disclosure: This post may contain affiliate links, meaning I get a commission if you decide to make a purchase through my links, at no extra cost to you.

This guide is designed to get YOU started with using the Dremel. When I bought my first Dremel, it was hard to find instructions and simple guides to get started with the Dremel. This article will serve as a general guide for Dremel and rotary tool users.

You probably have a lot of questions about using the Dremel, not everything is self-explanatory, so let me show you how you should approach getting started.

Content In this article:

- Types Of Dremel Rotary Tools

- Main Controls

- Understanding Collets

- Dremel Bits

- 6 Tips For Using The Dremel

- Attachments and add ons

- Common Questions About The Dremel

What Is A Dremel?

A Dremel is a rotary tool that is used for woodcarving, metalwork, engraving, cutting plastics, DIY projects, sanding, grinding, sharpening, and more. A Dremel uses bits that are attached in the chuck of the Dremel tool, different types of bits are used for different purposes. The shaft of the Dremel rotates from 5000 to 35000 RPMs.

The word Dremel can be a bit confusing. Dremel is actually the name of a company that is well known for producing power tools. But they specialize in rotary tools, so the Dremel name has become a common term for rotary tools.

And so, when people talk about using a Dremel, they are generally talking about the Dremel rotary tool or a rotary tool made by some other brand. Like Milwaukee for example.

Types Of Dremel Rotary Tools

Let’s get quickly get to know the different types of Dremel rotary tools. I will put them into three categories. We have the cordless rotary tools, we have the corded flagships, and then the DIY rotary tools.

The Flagship Dremel Models – Corded

Dremel 3000, Dremel 4000, Dremel 4300, Dremel 200, Dremel 100

The models listed above are the most common Dremel tools for people to buy. The Dremel 3000, 4000, and 4300 are very similar in use, they are powerful and have a fairly similar price point. The great thing about these models is that the speed control is a lot more versatile than the Dremel 100 and 200. You can choose speeds from 5000 RPMs up to 35000 RPMs.

The Dremel 200, and 100 are older models of the Dremel rotary tool. But they still hold up to the test of time. They are a fair bit cheaper than the other flagship models, and they will do most jobs you want them to do. But a big downside with the 100 and 200 models is their lack of speed control. The Dremel 100 only has one speed (3500RPM) and the Dremel 200 has two speeds (15000 and 35000 RPM)

The Cordless Dremels

Dremel 8220, Dremel Lite 7760, Dremel Micro 8050

Dremel 8220 – This is a powerful cordless Dremel tool. This tool is just as powerful as the corded Dremels. The greatest advantage of the tool is that you can use it anywhere without relying on a power outlet. The downside is that the battery only gives 30 – 45 minutes of use from a full charge. Dremel 8220 is good for tasks that can be done fairly quickly.

Dremel Lite 7760 – The Dremel Lite is just a less powerful version of the Dremel 8220. It has a less powerful motor, has a lower rpm range, and is smaller. Dremel 7760 is great for DIY work and simple tasks.

Dremel Micro 8050 – The Dremel Micro is one of the smallest rotary tools the Dremel brand makes. It is great for doing simple DIY work and simple tasks. Unlike the two other cordless Dremels, this tool does not have a battery that is removable. You will have to use the charging station to charge the built-in battery. ( Could Not Find A Shop That Sells This Tool, Might Be Discontinued )

The DIY Dremel

Dremel Stylo+ 2050

Dremel Stylo+ 2550 – This Dremel deserves its own category. In my opinion, it is the best DIY Dremel to use for small and light tasks. It is corded, very small, has a comfortable grip, and runs quietly. The one downside of this tool is that it is less powerful than many of the other models. The motor will stop if you apply too much pressure when using the tool.

Basic Dremel Controls

Dremel rotary tools are used in the same way, but with differences in design. The main components to know about are the start/stop button, speed control, and the spindle lock button.

Start and Stop Button/Slider

To start and stop the Dremel, there will either be a slider or a button. But it will be very easy to identify since it will have the universal power On and OFF symbol on it. It can also be presented as a 0 and a 1. Where 1 is ON and zero is OFF. The start and stop buttons/sliders have a blue color.

Speed Control

Most Dremels have some kind of speed control. With the exception being the Dremel 100, which is single speed. The speed control determines how fast the shaft will rotate, also called RPM. Depending on the model, the Dremel will have an RPM from 5000 to 35000.

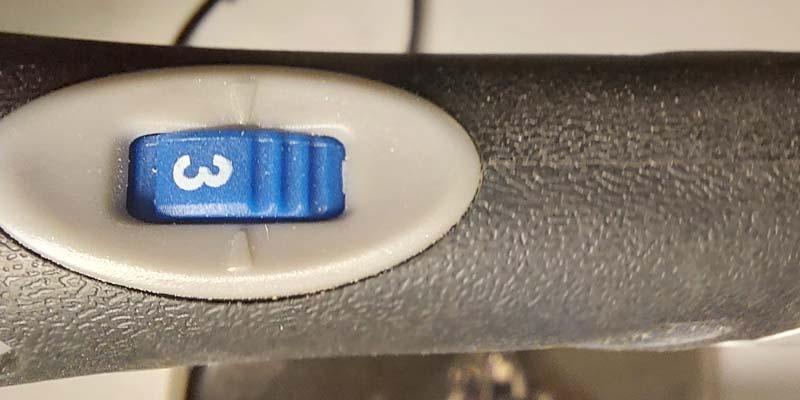

Some Dremels have a range of pre-determined speeds that you can switch between, this will be presented in the form of numbers (Ex. 1-5). Some Dremels has a slider where you can choose speeds throughout the whole range of RPM.

Spindle Lock Button

The spindle lock button, also called the shaft lock button or collet lock button is used to keep the spindle from turning when we want to release or tighten the bit in our Dremel.

To tighten and release the collet nut which holds the bit in place, we use the small wrench that is provided in the tool kit for the Dremel. Tighten or loosen the collet nut while holding down the spindle lock button.

The spindle lock button will have a logo of a lock on it.

Understanding Dremel Collets

A collet for the Dremel is a metal piece that you put inside the tip of the Dremel. The collet is designed to clamp on hold on to any object that is inserted into the chuck of the Dremel when the collet nut is tightened. The collet keeps the bit secured and tight when you are using the Dremel.

We need to use different sizes of collets when we want to use bits with varying shank sizes. The standard shank size for Dremel Bits is 1/8-inch or 3.2mm. But sometimes we have to use a bit that is not made by the Dremel brand, or maybe we have to use a drill bit with a smaller shank size.

The Collets Comes in Four Sizes. 1/32-inches (0.8mm), 1/16-inches (1.6mm), 3/32-inches (2.4mm) and 1/8-inches (3.2mm).

If you do not want to deal with collets, you can use the Quick Change Chuck. The Quick Change Chuck acts like a keyless chuck on a hand drill. And will take bits with shank sizes that are up to 1/8-inch or 3.2mm.

Dremel Bits

When talking about rotary tools, a bit is a small changeable accessory that you secure to the chuck of the tool. The bit then spins at the desired RPM. Bits can be changed depending on what we are going to use them for. Some bits are good for sanding, some are good for cutting steel and some are good for polishing, and so on.

The Dremel bits are really what makes the Dremel such a good universal and versatile tool. There is a wide variety of different bits for the Dremel and you will find one that is suitable for any task.

This will be a simple introduction to the most common Dremel bits. If you want a more detailed guide for the Dremel Bits, check out the article below.

The Ultimate Guide For Dremel Bits | All Dremel Bits Explained

Sanding Bits – Sanding bits comes in many shapes. You have sanding drums, sanding discs, Abrasive buffing wheels, flap sanders. Sanding bits are used on metal and wood, and are used to clean up surfaces and sections of material.

Grinding Stones – Grinding stones are used for sharpening tools, deburring metal, and metalwork in general. Grinding Stones come in different sizes, shapes, and coarseness.

Polishing Bits – Polishing bits are used to polish and clean metal. Buffing wheels are used with mandrel #401, before you start polishing you run the buffing wheel through some polishing compound.

Diamond Bits – Diamonds bits are used for fine detailed work in wood and metal, they can also be used for engraving. The bits are coated with a diamond powder in different coarseness and last for a long time.

Cutting Wheels – Cutting wheels are used for cutting different materials. Dremel makes specialized cutting wheels for different materials. #SC456 is for metal, #SC476 is for plastic, #EZ544 is for wood.

Drilling Bits – Drilling bits are used to drill holes in metal, plastics, wood, and plexiglass. The largest drilling bits the Dremel can use are 1/8-inch or 3.2mm. So it used to drill small holes.

Mandrel Bits – Mandrels are used when you have bits that use a material that wears out and needs to be replaced after a certain time. Examples of mandrels are the sanding drum mandrel, the EZ-lock mandrel, and the mandrel for buffing wheels.

Steel Brushes – Steel brushes are used for metalwork and cleaning. They are also effective at removing rust.

6 Tips For Using The Dremel

When using the Dremel it is always a good idea to wear protective glasses and gloves. And if you are producing any dust while using it, you should also wear a dust mask.

How you should use a Dremel will entirely depend on what you are using it for. But there are some good techniques and practices that we can use, so you can learn to use the tool safely and make yourself comfortable with using it.

1. Unplug The Power When Changing Bits

From time to time we have to change bits on our Dremel. Maybe you need a new bit for a different task or the bit you are using has become worn out and you need a new one.

When changing a bit it is always a good idea to unplug the Dremel power cord from the socket. Accidentally turning on the power while changing bits is more common than you might think. On some Dremel models, like the Stylo+ 2050, the On and Off button and the Spindle Lock button for changing bits are very similar.

Here is a video on how to change a bit:

2. Start The Dremel Unobstructed

Only start the Dremel when it is not in contact with other material to avoid the Dremel bit from jumping and being guided by the material on startup.

Start the Dremel, then do your cut.

It can also be a good idea to not power on the Dremel at max RPM.

3. Use The Right RPMs

For most of the time when using a Dremel, setting the RPM to somewhere in the middle of the scale will be appropriate. The most common RPM I find myself using the Dremel at is anywhere from 20000 to 25000 RPMs.

But for some bits, the optimal RPM will be different. Dremel has its own recommendations for the max RPMs you should run the different bits at.

Dremel Max RPM Recommendations:

- Sanding Drums: 35000 RPMs

- Cutting Wheels: 35000 RPMs

- Polishing Buffs: 20000 RPMs

- Sandig Disc:s 20000 RPMs

- Grinding Stones: 20000 RPMs

Finding the right RPMs will be subjective and change depending on the user. So your best bet is to test the different bits at different RPMs and see what you like the best and are comfortable with.

4. Let The Dremel Do The Work

When using the Dremel for cutting steel, cutting wood, cleaning rust, and so on, let the tool do the work. Do not use too much force on the bits or the tool.

Using too much force will cause the bits to wear out quicker, it will increase the probability that you lose control of the tool, and it will be bad for the motor.

Cutting steel is a great example, it can be hard to be patient if you are cutting a thick piece of hardened steel with the Dremel. It is tempting to use a little bit of extra force to cut through the steel quicker. The result will be that the cutting discs wear out or even breaks, and the tool will have a big chance of tearing out while cutting.

Be patient

5. Use Protective Glasses, Gloves And A Dust Mask

When using the Dremel it is always a good idea to wear protective glasses and gloves. And if you are producing any dust while using it, you should also wear a dust mask.

6. Explore The Thousands Of Different Uses

The best way to get to know your Dremel is to use it. If you get in the habit of using the Dremel whenever you can you will learn to use the tool at lightning speeds. The Dremel is a truly versatile tool, and you will be surprised how often it comes in handy.

Attachments For The Dremel

Attachments are add-ons that you can get for your Dremel to increase the capabilities of the tool. You can get attachments for sharpening, for better grip on the Dremel, for making the Dremel into a router and so much more.

The attachments are very helpful and enable you to get the most out of your Dremel. You can get the right attachments to your specific needs.

There are so many attachments, so I made an entire article on attachments for the Dremel:

Dremel Attachment Guide – All Attachments Explained

I will include the three attachments I find the most useful below

1. Flex Shaft #225-01

The Flex Shaft is by far the most useful attachment for the Dremel. Especially if you are going to use the Dremel for long periods at a time. For example, if you are wood carving, engraving, or shaping anything.

The Flex Shaft is basically a stylo for your Dremel. It reduces the weight you have to hold while using the Dremel drastically and gives you the ability to be more flexible and smooth in your movements. When using the Flex Shaft you need to hang up your Dremel motor somewhere.

2. The Right Angle Attachment

The Right Angle Attachment gives you the ability to fasten and run your bits at an angle. This is very helpful when you are working in places that can be hard to reach and when the tool has to cut at specific angles.

An especially good application for this attachment is when you want to cut a metal screw or bolt. The cut will be made It gives you the ability to do 90-degree cuts on flat surfaces, get into tight and “hard to get to” spots, and increase visibility when working. Contrary to the name it can be used at all angles.

3. Dust Blower #490

The Dremel Dust Blower removes dust as you are using the Dremel. Just thread the attachment on after the collet and it is ready to use.

Dust build-up can be an annoyance when using the Dremel, the dust blower removes the build-up of dust so you get a clearer vision of what you are doing. The Dremel Dust Blower is especially helpful if you are doing wood carving and engraving.

Common Questions About The Dremel

What is the best Dremel?

What the best Dremel is will depend on what you are going to use it for. But I can still give my recommendation.

The best all-around Dremel I recommend to most people is the Dremel 4000 With The Flex Shaft Attachment. This Dremel and Flex Shaft combo will be a good buy for most people.

If you really want the ability to bring the Dremel with you anywhere and do not want to depend on a power outlet. Then you should get the Dremel 8220.

If you do DIY projects or crafting and need the Dremel for some light tasks. Then you might be better of getting the Dremel Stylo+

Cordless Or Corded Dremel

In my opinion. The Corded Dremels are more convenient than the cordless version. Then you do not have to deal with the tool running out of battery and waiting for the battery to recharge. The run time of the cordless version is also fairly low if you want to use the Dremel over a prolonged period.

What To Do If The Bit Or Collet Gets Stuck

If you get a stuck bit or collet, you should go and read this article.

Bit Or Collet Stuck In Your Dremel? – 3 ways to fix it

Conclusion

That was it for this article. Now get to work and use that Dremel.