Disclosure: This post may contain affiliate links, meaning I get a commission if you decide to make a purchase through my links, at no extra cost to you.

A Dremel and Drill might seem like two very similar tools. Both of them have a shaft that spins quickly, both can be used to drill holes in all kinds of materials and many of the bits that the Dremel uses, can also be used with a drill. But a drill and a Dremel are two completely different tools that are used for different purposes. Let us have a look at the differences.

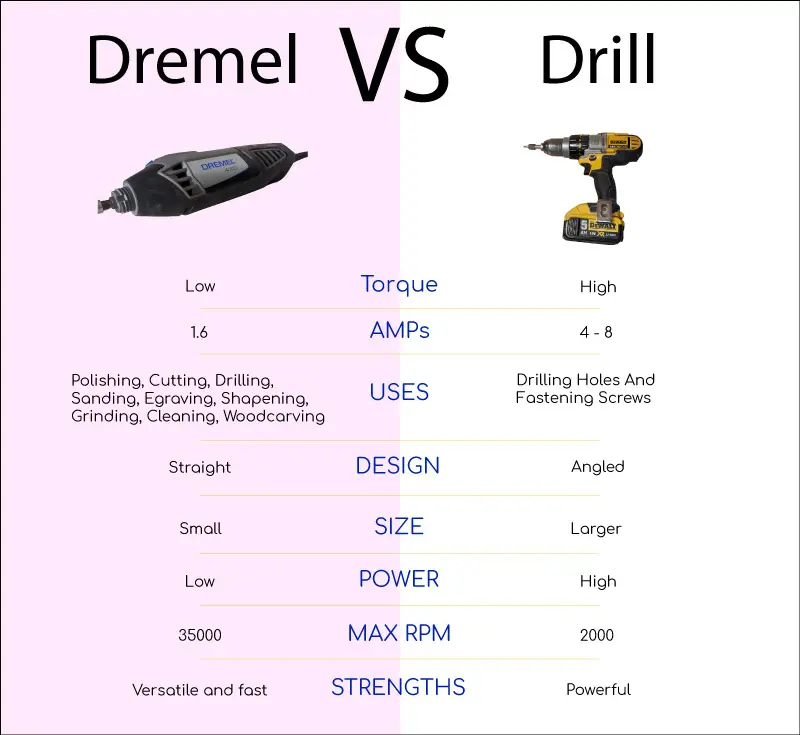

The main difference between a Dremel and a drill is the power (torque) of the tool and the RPMs of the tool. A Dremel has low torque and a max rpm of 35000. A drill has high torque and a max rpm of 2000. A Dremel is used for sanding, grinding, engraving, cutting, and more. A drill is used to drive screws and drill holes.

In this article I will go more into depth on the differences between a Dremel and a drill, we will talk about how the different tools are used, and also some of the similarities and overlapping uses of the tools.

What Is A Dremel?

A Dremel is a rotary tool. A rotary tool like the Dremel uses bits that have a maximum shank size of 1/8″ (3.2mm). The different bits are used for very different tasks, such as cutting, sanding, grinding, sharpening, engraving, routing, and more. The rate that the shaft of a Dremel spins at is very fast, a Dremel will have an RPM ranging from 5000 to 35000.

The Dremel is mainly used for tasks that do not require too much power from the motor, if the motor senses too much resistance it will have to work hard and eventually overheat or turn off.

Some great practical uses for the Dremel are deburring metal edges that have been cut, engraving designs into glass or stone, and cutting things like screws and nails.

What Is A Drill?

A drill is a tool that rotates larger bits at a low rpm and with high torque. A drill is mainly designed to drill holes in a wide variety of materials including wood and metal and is also used for driving screws and fasteners. A drill is a powerful tool that can handle heavier tasks and more resistance than for example a Dremel.

Example Of A Drill Use – When we are a new piece of furniture and we need to use the drill to fasten the screws. Or when we need to hang up a shelf, and we need to fasten it to the wall with screws so it does not fall down

The Main Differences Between A Dremel And A Drill – Table

| Metric | Dremel | Drill |

|---|---|---|

| Torque | Low | High |

| AMP (Electricity Flow Rate) | 1.6 AMPs | 4 – 8 AMPs |

| Main Uses | Polishing, cutting, drilling, sanding, engraving, sharpening, grinding, cleaning, woodcarving, and more | Drilling holes and fastening screws |

| Attachments | Are designed to work well with attachments | Not initially designed to be used with attachments. But useful attachments have been developed to work with drills. |

| Design | Straight | Angled |

| Size | Small | Larger |

| Power | Low | High |

| Max RPMs | 35000 | 2000 |

| Strengths | Versatile and fast | Powerful, can drill and screw into dense materials |

Dremel Vs Drill: Main Differences

Torque – Dremel Vs Drill

To say it in simple terms, torque is the force a tool produces to turn an object. A drill will be able to produce a lot more rotational power than a Dremel will. A drill will be able to produce enough power to uphold the rotation of the spindle while facing large amounts of resistance. If a Dremel faces too much friction or resistance while in use, the rotation of the spindle will slow down and the motor will overheat or stop.

AMPs (Electricity Flow Rate) – Dremel VS Drill

AMPs is a unit of measurement that measures how much electricity the motor can constantly make use of. Higher amperage helps the motor stay cool and not overheat over an undefined period of time. The main Dremel models can use 1.3 – 1.8 AMPs of constant power, cordless drills can use 4 – 8 AMPs of constant power.

Comparing the amperage between a Dremel and a drill shows that drills can make use of more electricity at any given time, and indicate a more powerful tool. But since the tools are used in such different ways, we cannot come to any conclusions by looking at the amperage of the tools.

RPMs (Rounds Per Minute) – Dremel VS Drill

RPMs measures how many times the spindle of a tool turns a full rotation in a minute. A Dremel has an extremely fast RPM rate ranging from 5000 to 35000 RPMs. A drill has a low RPM rate compared to the Dremel with an rpm ranging from 400 to 2000 RPMs. The low RPM setting on a Dremel is higher than the highest RPM setting on a drill.

The fast RPMs of Dremel tools make it great for doing detailed work and surface work where the tool faces little resistance. Such as engraving, deburring metal edges, and light sanding.

The relatively low RPMs of a drill make it good for more heavy-duty work. Like driving a screw into a hardwood 2×4 or even drilling holes in concrete.

Main Uses – Dremel VS Drill

The main uses of a Dremel are engraving, wood carving, sanding, grinding, cutting, polishing, routing, cleaning, and more. The main uses of a Drill are to drill holes in a wide variety of materials and substances and also drive screws and fasteners. The Dremel is used for light tasks, while a drill is used for tasks that require more power.

Attachments – Dremel VS Drill

A Dremel is a versatile tool that is designed to use many different attachments for different purposes. For example, a Dremel has attachments that can make it into a plunge router, a chainsaw sharpening kit, or a drill press. A drill is not initially designed to be used with attachments, but useful attachments have been invented and developed that can be used with a drill.

Check Out Some Cool Dremel Attachments! – Article!

Check Out Some Cool Attachments For Drills! – Article!

Design – Dremel VS Drill

The main difference in the design between a Dremel and a drill is the angle of the tool. A drill has a 90-degree angle between the handle and the bit. This makes it easier for the user of the drill to produce force towards the task being performed. A Dremel is designed in a single straight matter, and the bit sits in the same direction as the handle. This gives you more control of the small bits and is better for detailed work.

A Dremel is designed so your hand sits close to the bit you are using when you are using it, to give you more accuracy.

Strengths – Dremel VS Drill

The strength of the drill is that it is designed so it is able to produce large amounts of power and torque to drill holes and fasten screws. The strength of the Dremel is its versatility, with a different bit for every need and an attachment for every situation.

Similarities And Overlapping Uses Of A Dremel And A Drill

There are not many overlapping uses between a Dremel and a drill. But there are some. Both can use small drill bits, both of them rotates as their main function, and both can use simple sanding drums. Other than that, they really are two different tools, designed for completely different purposes.

My favorite Dremel Pick

The Dremel 4000 is one of the flagship models of the rotary tools that the Dremel produces. This is the Dremel I own and use almost daily. It is one of the more powerful Dremel models and among all the Dremel models, I believe this is the tool where you get the best value.

Learn More About The Different Dremel Models! Check Out This Dremel Beginner Guide!

My Favorite Cordless Drill

DEWALT 20V MAX XR Hammer Drill Kit, Brushless, 3-Speed, Cordless (DCD996P2)

Dewalt is one of the most trusted brands when it comes to cordless drills. I have an older version of this Dewalt XL drill. This drill will provide everything you would want in a Drill.

Common Questions About Dremel And Drills

Will Dremel Bits Fit In A Drill?

A cordless drill with a keyless chuck will be able to hold Dremel bits. The largest Dremel bits have a shank size of 1/8-Inches (3.2mm). If the chuck of your drill can hold bits that are 1/8-inches and smaller, then the bit will fit in your drill.

Will Cordless Drill Bits Fit In A Dremel?

A cordless drill bit will only fit in a Dremel if it has a shank size smaller than 1/8-inches (3.2mm). Most cordless drill bits have a larger shank size than 1/8-inches, so most drill bits will not fit in a Dremel. Smaller drill bits to drill holes are the main bits that are frequently used in both Dremel tools and Drilling tools.

Can I Use My Drill As A Dremel?

You can use your cordless drill as a rotary tool but it will not have the same efficiency or accuracy compared to using a Dremel. The lower RPMs, the weight of the tool, and the distance from the handle to the bit will make it hard to use a drill as a rotary tool effectively. Bits for rotary tools are also designed for higher RPMs.

Can I Use My Dremel As A Cordless Drill?

A Dremel can in certain situations be used for the same purposes as a cordless drill. A Dremel can drill small holes that are 1/8-inches (3.2mm) in wood, metal, and other materials. But a Dremel can not be used as a cordless drill if you want to fasten screws or do work the needs large amounts of power and torque.

Can Dremel Bits Fit In Other Rotary Tools?

Most rotary tools like the Dremel uses bits that have a shank size of 1/8-inches (3.2mm) or smaller. This means that Demel bits can be used in other rotary tools. Other types of rotary tools like a Die Grinder will take bits with shanks sizes of 1/8-inches (3.2mm) and 1/4-inches (6.4mm.